2025 Solder Tabs: Revolutionizing Electronic Assembly

Related Articles: 2025 Solder Tabs: Revolutionizing Electronic Assembly

- 2025 Subaru Truck: The Next-Generation Pickup For Adventure And Utility

- Current Interior Design Trends 2025: A Glimpse Into The Future Of Home Decor

- 2025 Yearly Calendar Printable Free PDF: Plan Your Year With Ease

- How Many More Days Until June 14th, 2025?

- The 2025 Wisconsin Supreme Court Election: A Battle For The Soul Of The Court

Introduction

In this auspicious occasion, we are delighted to delve into the intriguing topic related to 2025 Solder Tabs: Revolutionizing Electronic Assembly. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

Video about 2025 Solder Tabs: Revolutionizing Electronic Assembly

2025 Solder Tabs: Revolutionizing Electronic Assembly

Introduction

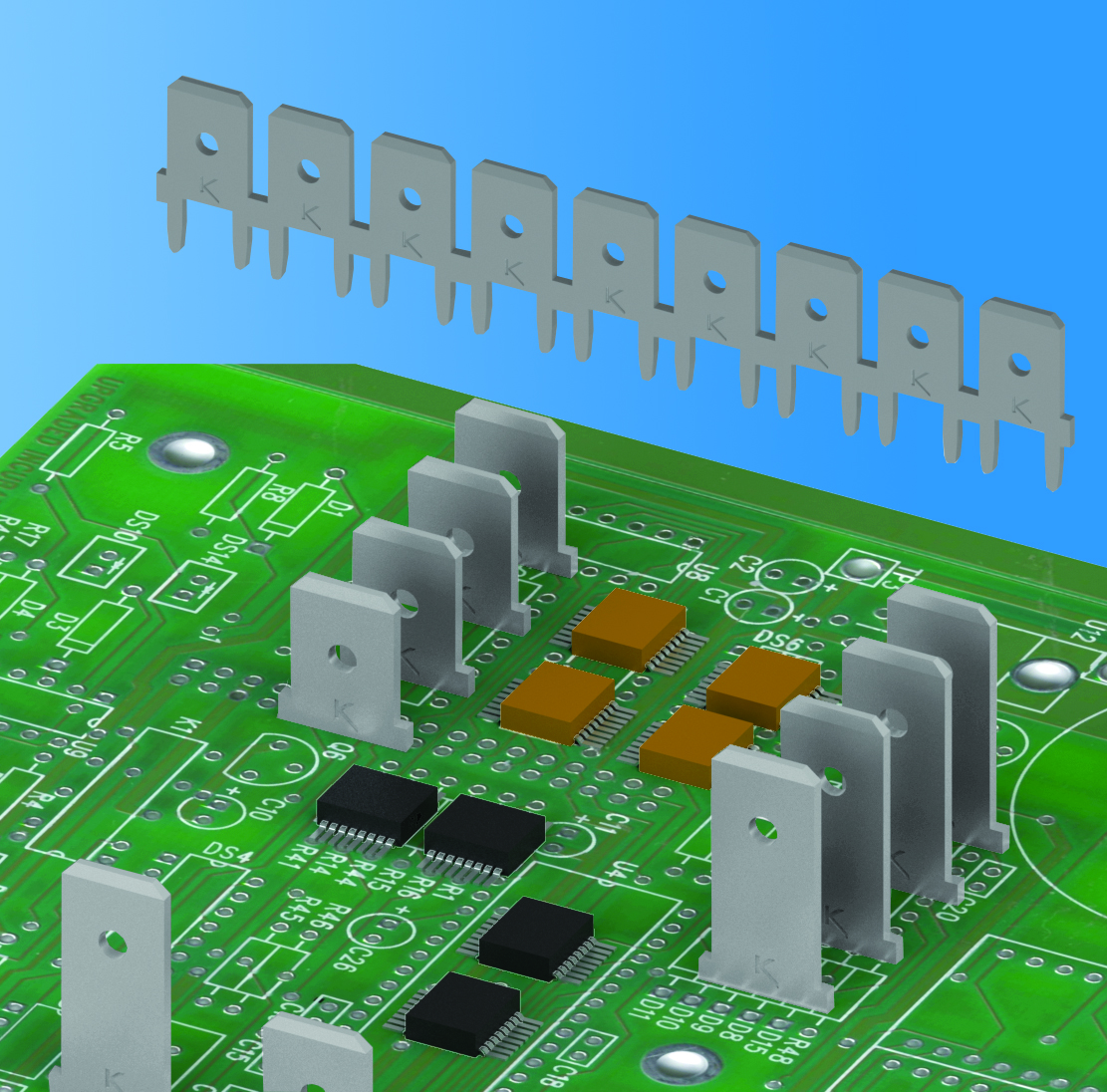

In the realm of electronic assembly, the humble solder tab plays a crucial role in ensuring reliable and efficient connections between components. However, traditional solder tabs have limitations that can hinder productivity and compromise performance. To address these challenges, the industry has introduced a groundbreaking innovation: the 2025 solder tab.

2025 Solder Tab Design and Features

The 2025 solder tab is a revolutionary design that redefines the standards of electronic assembly. It features a unique shape and construction that offers numerous advantages over conventional solder tabs.

Key Features:

- Precision Geometry: The 2025 solder tab is manufactured with precise tolerances, ensuring consistent dimensions and a perfect fit for component leads. This precision eliminates misalignment and reduces the risk of solder bridging, improving assembly quality and reliability.

- Extended Solder Area: The solder tab’s extended solder area provides ample surface contact between the component lead and the solder joint. This increased surface area enhances the mechanical strength of the connection and reduces the likelihood of solder joint failure due to stress or vibration.

- Optimized Solderability: The 2025 solder tab is engineered with a solderable surface that promotes optimal solder wetting. This surface is free from contaminants and features a uniform solderability, ensuring consistent and reliable solder joints.

- Low-Profile Design: The solder tab’s low-profile design minimizes the height of the assembled component, allowing for compact board layouts and improved airflow. This feature is particularly beneficial in applications where space constraints are a concern.

Benefits of Using 2025 Solder Tabs

The 2025 solder tab offers a multitude of benefits that enhance the efficiency and reliability of electronic assembly processes.

- Increased Productivity: The precision geometry and extended solder area of the 2025 solder tab reduce misalignment and improve solderability, leading to faster and more efficient assembly.

- Enhanced Reliability: The increased mechanical strength and optimized solderability of the 2025 solder tab ensure robust and durable connections, minimizing the risk of solder joint failure and extending the lifespan of electronic devices.

- Improved Performance: The low-profile design of the 2025 solder tab reduces component height, allowing for improved airflow and thermal management. This can enhance the performance and longevity of electronic components.

- Cost Savings: The increased productivity and reliability offered by the 2025 solder tab can lead to significant cost savings through reduced assembly time, rework, and warranty claims.

Applications of 2025 Solder Tabs

The 2025 solder tab is a versatile component that finds applications in a wide range of electronic devices, including:

- Consumer electronics (e.g., smartphones, tablets, laptops)

- Automotive electronics (e.g., engine control units, navigation systems)

- Industrial electronics (e.g., programmable logic controllers, sensors)

- Medical devices (e.g., pacemakers, defibrillators)

- Aerospace electronics (e.g., flight control systems, radar systems)

Conclusion

The 2025 solder tab represents a significant advancement in the field of electronic assembly. Its precision geometry, extended solder area, optimized solderability, and low-profile design offer numerous advantages over traditional solder tabs. By utilizing 2025 solder tabs, manufacturers can increase productivity, enhance reliability, improve performance, and reduce costs. As the electronics industry continues to evolve, the 2025 solder tab is poised to become an indispensable tool for creating high-quality and reliable electronic devices.

Closure

Thus, we hope this article has provided valuable insights into 2025 Solder Tabs: Revolutionizing Electronic Assembly. We hope you find this article informative and beneficial. See you in our next article!